Amidst supply chain disruptions and fluctuations in the economy, the manufacturing industry is building back – and fast. Production and capacity utilization rates are up across the country, despite industry-wide problems like an aging workforce and labor shortages. Challenges aside, there’s even more growth projected on the horizon.

Much of this predicted growth can be traced to a widespread push to accelerate adoption of advanced and digital workflows to support better and faster decision-making within smaller teams.

…45% of manufacturing executives surveyed expect further increases in operational efficiency from investments in industrial Internet of Things (IIoT) that connect machines and automate processes.

-- Deloitte’s 2022 manufacturing industry report

At Hirsh Precision, we have always viewed technology like robotics and software as enablers that create opportunities to increase production throughput and improve the efficiency of our inspection process. The various forms of automation we have implemented empower our experienced manufacturing professionals to do more technical work – but they could never replace them.

People are the best problem solvers around! Designing stable processes through creative, technical problem solving is always a prerequisite to automation. As our team moves into our new headquarters and continues to grow, incorporating robotics and automation will be essential to successfully reaching our growth goals.

Hirsh Leadership attends Automation Conference

This past month, our President and CEO Peter Doyle and COO Patrick Tarvin attended the Automate conference produced by the Association for Advancing Automation. Our leadership team saw the latest innovations in manufacturing and identified opportunities to integrate all sorts of new technology, including but not limited to:

- AI-enabled vision systems

- High-mix machine tending

- AMRs

- Rapid inspection and metrology systems

- Automation of post-machining processes, such as deburring, cleaning, and packaging parts

Coming away from the conference, our leaders identified key opportunities where robotics, automation, and our team’s future growth were concerned.

The Future of Robotics and Automation at Hirsh Precision

Our team has not been shy about growth and continuous improvement efforts in the past, and we’ve shown that again this past year. From acquiring a new 65,000 square-foot industrial facility to investing in a second Fastems automated manufacturing system, we’ve been taking significant steps to increase our production and output using robotics and automation.

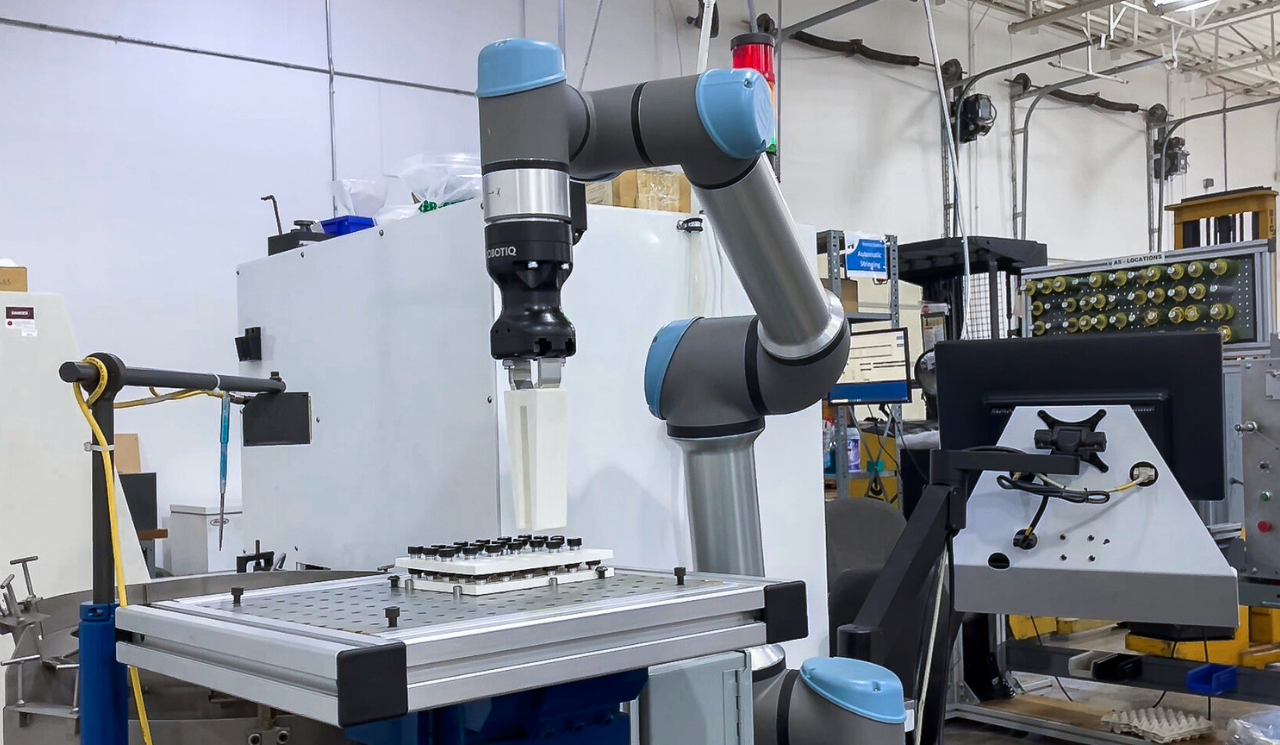

Additionally, we launched our first-ever Robotics Engineering team. With the long-term goal of understanding how automation can help Hirsh become a more productive and consistent supplier for our customers, the team is taking on several projects to identify tasks that would free up our team members to focus their skills and efforts where they can add the most value.

Our Robotics Engineering Team is working to incorporate automated movement for parts, carts, and chip bins in our new facility space. Given the size of our Frederick facility, this will make our team more efficient and ultimately save our customers’ time and money.

Additionally, the Robotics Engineering team is also developing a Cobot that can assist our team members with those very post-machining processes mentioned earlier, such as part finishing and packaging.

I think the robotics team can really help push Hirsh to the forefront of advanced manufacturing here in the US. Manufacturing companies that survive into the future…will be the ones that invest in robotics and automation now.

-- Jory Whitmore, Quality Engineer and Robotics Team Lead

As we plan for the future and continue scaling our productivity, quality, and customer experience, steady investment in automation and robotics will allow us to keep raising the bar in advanced manufacturing and providing the collaboration and support that our customers need.

Our ideas are being tested and refined on a daily basis – stay tuned to hear more about our growing capabilities!