A component’s ductility directly influences its ability to perform in high-stress environments and withstand extended service life. Sectors such as construction, automotive, and aerospace consistently require ductile materials to optimize manufacturing processes and uphold stringent safety standards.

In CNC machining, ductility plays a pivotal role by influencing how materials respond to cutting forces and mechanical stress. Metals with high ductility, such as aluminum and copper, can be shaped into intricate geometries without cracking, which supports the creation of smoother surfaces and reduces the risk of fractures during bending or forming operations.

This article will briefly look at how ductility shows up in commonly machined metals before digging into how ductility is calculated in a particular alloy. Ductility measurements can help determine whether a material will perform reliably under load, especially in applications where deformation or impact resistance is critical.

Engineers should leverage a thorough understanding of ductility to not only choose the right material, but to optimize their component's design prior to moving production. For example, materials exhibiting high ductility are susceptible to deflection under machining forces. This can lead to dimensional inconsistencies if not accounted for in the design process.

Ductility in Commonly Machined Metals

Ductility describes the extent to which a material can be elongated, stretched, or drawn into fine wires under tensile load without experiencing fracture. It quantifies a metal's ability to sustain plastic deformation before breaking—a critical consideration in the production of wires, rods, cables, and thin metal sheets for a variety of industrial and engineering applications.

High Ductility

Metals with high ductility are more likely to undergo plastic deformation rather than fracture when subjected to stress. When a material possesses both substantial strength and ductility, it typically exhibits greater toughness, enabling it to absorb more energy before failure.

Low Ductility

Metals with low ductility are inherently brittle and tend to fracture with very little plastic deformation when exposed to tensile stress, making them susceptible to abrupt and catastrophic fracture under load.

Ductility differs significantly among metals and is influenced by several variables, including material purity and crystalline structure. Metals possessing tightly packed atomic arrangements—such as gold and silver—demonstrate notably higher ductility.

In widely machined metals such as aluminum, stainless steel, titanium, and various alloys, ductility influences how the material deforms under machining forces, its response to localized stresses, and its ability to withstand secondary operations like bending, forming, or assembly.

|

Metal |

Typical Ductility |

Notes on Machinability and Design Considerations |

|

Tool Steel |

Very low |

Prone to cracking during machining; requires careful stress management |

|

Titanium |

Low to moderate |

Heat buildup during machining can affect surface finish; generous radii and stress relief are recommended |

|

Stainless Steel |

Moderate |

Prone to work hardening; sharp tools and slower feeds help manage machining stress |

|

Bronze |

Moderate to high |

Excellent machinability; good for wear-resistant parts and bushings |

|

Alloy Steel |

Moderate to high |

Good balance of strength and ductility; suitable for structural parts; heat treatment affects final ductility. |

|

Brass |

High |

Easy to machine; ideal for fittings and decorative parts; excellent chip control. |

|

Mild Steel |

High |

Easy to machine and form; ideal for welded or press-fit assemblies |

|

Aluminum |

Very high |

Highly ductile; smooth chip formation; ideal for thin-walled or complex geometries; tolerates aggressive machining |

|

Copper |

Very high |

Excellent thermal and electrical conductivity; soft and easy to machine but requires care to avoid smearing. |

A thorough understanding of a metal’s ductility enables mechanical engineers to predict how a part will respond throughout machining and subsequent processes. This knowledge is essential for making informed choices about tolerances, surface finishes, and post-processing procedures—ultimately ensuring that final components satisfy both application-specific and manufacturing criteria.

How Ductility is Measured

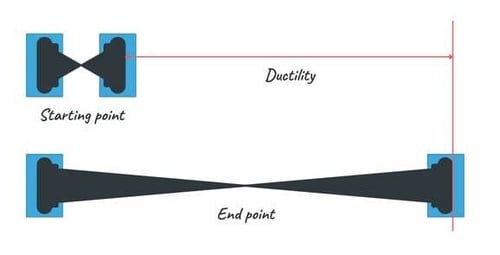

Ductility is typically quantified by how much a material can deform plastically before fracture, and the most common way to measure it is through a tensile test. In this test, a standardized specimen is pulled apart in a controlled manner until it breaks. The two primary indicators of ductility from this test are elongation and reduction of area.

Both of these measurements are influenced by factors like strain rate, temperature, and specimen geometry, so it’s important to follow standardized testing procedures — typically outlined in ASTM E8 or ISO 6892 — to ensure consistency.

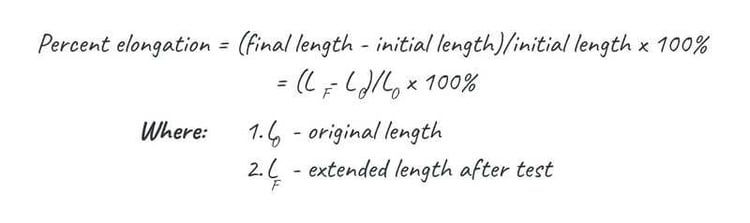

Elongation

Elongation is calculated by measuring the change in length of the specimen after fracture compared to its original gauge length. It’s usually expressed as a percentage, and it gives a direct sense of how much the material stretched before breaking. The higher the percentage, the more ductile the material.

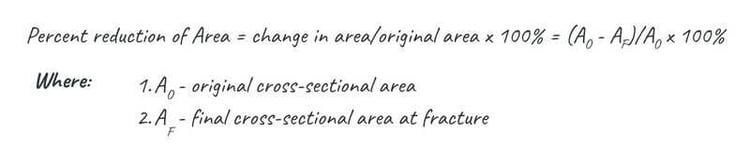

Reduction of Area

Reduction of area, on the other hand, is determined by measuring the cross-sectional area at the fracture point and comparing it to the original area. This metric reflects how much the material necked down before failure, which is another hallmark of ductile behavior.

It's calculated by the following equation, using the tensile test.