Your part meets dimensional spec—but will it survive in service? That’s the question every engineer should be asking. In aerospace, medical devices, and biotech, dimensional accuracy is table stakes. It’s expected, it’s audited, and it’s rarely the differentiator.

The real battleground for performance and reliability lies in surface integrity—the unseen characteristics that dictate fatigue life, corrosion resistance, and functional performance. Post-processing isn’t just about aesthetics or smoothing out machining marks. It’s a critical engineering function that determines whether your part thrives under operational stress or fails prematurely.

In regulated industries, surface integrity is tied directly to compliance, lifecycle cost, and user safety. In this post, we'll walk through why and how to treat surface finishing like a strategic priority.

What is Surface Integrity and Why Does it Matter?

Surface integrity is more than a polished look. It’s a multi-dimensional property encompassing surface roughness, microstructure, residual stresses, and contamination. Each of these factors influences how a component interacts with its environment and performs under load.

Consider the performance drivers across industries. In aerospace, fatigue strength is everything. A single micro-crack from aggressive grinding can propagate into catastrophic failure. In medical devices, biocompatibility hinges on surface cleanliness and texture, impacting osseointegration and patient outcomes. Industrial and biotech systems demand corrosion resistance, where surface chemistry and finish dictate longevity in harsh environments.

Standards reinforce this reality. NADCAP mandates strict process controls for aerospace finishing. FDA and ISO 13485 require validated cleaning and finishing protocols for implants. These aren’t optional—they’re enforced through audits and certifications.

| Standard | Usage | Objective | Example of Application |

|---|---|---|---|

| ISO 2768 | Defines standard tolerances for linear, angular, and geometric features in unassociated metal parts | Maintains size uniformity across manufacturing and finishing stages | Specifying “ISO 2768-m” tolerance for a 50 mm CNC-machined metal shaft |

| ISO 1101 | Specifies limits for variations in form and position of part features | Ensures geometric standards are met despite dimensional changes from finishing | Specifying ⊥ 0.1 per ISO 1101 sets a 0.1 mm perpendicularity tolerance for a hole relative to a datum plane. |

| ASME Y14.5 | Indicates how GD&T symbols define permissible variations in part size and shape using controls like position. | Delivers consistency and precision throughout manufacturing and finishing | Using positional tolerance: Ⓟ 0.2 | ⌀10 | A B C* |

| ASTM D618 | Covers the procedure for conditioning plastics after molding prior to testing, evaluating the effects of thermal and chemical smoothing | Stabilizes sample dimensions by conditioning to equilibrium before further processing | Condition plastic samples for 48 hours at 50°C, followed by 96 hours at 23°C and 50% relative humidity prior to chemical smoothing. |

Surface integrity isn’t a buzzword; it’s a compliance and performance imperative.

In Spec vs. Performance Finishing

Meeting dimensional tolerance doesn’t guarantee functional success. A part can pass inspection and still fail in service because surface integrity was compromised. This disconnect is where many “good” parts ultimately fail—assuming that tolerance equals performance.

Failure modes tell the story, and real-world examples underscore the stakes.

|

Failure Mode |

Cause |

Industry Impact |

|

Micro-cracks |

Aggressive grinding or machining |

Reduced fatigue life in aerospace |

|

Embedded Abrasives |

Uncontrolled polishing |

Contamination risk in medical implants |

|

Residual Tensile Stress |

Improper shot peening or heat treatment |

Structural failure under cyclic loads |

These failures aren’t isolated—they’re systemic when finishing is treated as a secondary concern. The cost? Warranty claims, lost contracts, and reputational damage.

Just as each surface finishing method imparts different properties, each method also has a unique impact on a part’s dimensions. For some techniques, like media tumbling or bead blasting, the impact is negligible. For techniques like electropolishing or powder coating, the impact is greater and can result in either material loss or gain.

Often, the change is minor; we’re talking millimeters after all. But in the world of precision components and complex assemblies, every micron matters. The table below lists the most common types of surface finishes and compares the amount of thickness that gets added or removed to a completed part.

| Surface Finish Method | Standard Thickness |

| Anodize | 5 - 150 µm |

| Powder Coat | 50 - 150 µm |

| Electroplating | 2 - 25 µm |

| Electroless Plating | 2.5 - 50 µm |

| Black Oxide | 0.5 - 1.0 µm |

| Media Blasting | -- |

| Passivation | -- |

| Chemical Conversion Coating | -- |

When considering a surface finish (or finishes) for your parts, you need to understand not only how each method impacts dimensional accuracy but also how it will impact that part's performance in the field.

Engineering Surface Integrity

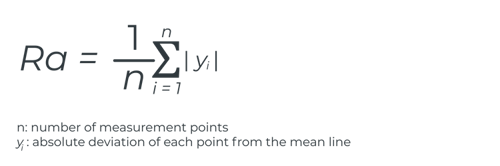

Surface integrity is measurable and controllable, but it requires moving beyond basic metrics like Ra.

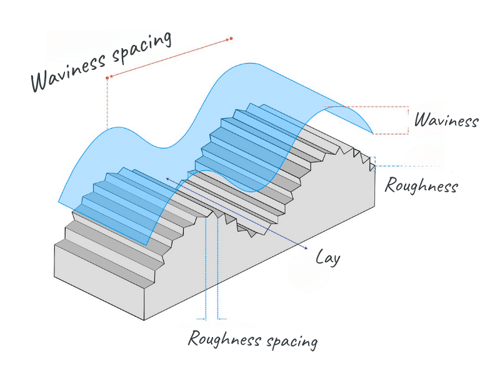

While Ra captures average roughness, it ignores waviness, lay, and microstructural anomalies that influence fatigue and corrosion.

There's a variety of metrology equipment you can use to monitor and control dimensional changes as a result of post-processing. The most common tools include:

- Coordinate Measurement Machines - CMMs excel at precision, achieving measurements within micrometers (0.001 mm), far surpassing the typical accuracy of digital calipers (0.01 mm)

- Laser scanners - a non-contact measurement tool that generates high-res 3D models that get compared to CAD drawings for dimensional change

- Optical comparators - project a part's profile onto a screen so you can visually compare against pre-set standards

- Surface roughness testers - determine surface finish quality by identifying changes from a post-process that would affect dimensional accuracy

Advanced metrology tools such as white light interferometry and 3D profilometry provide a complete picture, enabling engineers to quantify surface characteristics with precision.

|

Tool |

Measurement Capacity |

Application |

|

White Light Interferometry |

3D surface mapping |

High-precision aerospace components |

|

Stylus Profilometer |

Ra, Rz, waviness |

General industrial parts |

|

SEM (Scanning Electron Microscopy) |

Microstructural analysis |

Failure investigation and R&D |

Process control is equally critical:

- Controlled deburring and edge finishing prevent stress risers

- Heat treatment and stress relief stabilize microstructure and residual stresses

- Surface prep for coating adhesion ensures functional layers bond effectively, extending component life

These aren’t optional steps—they’re engineered interventions that safeguard performance.

Emerging technologies are reshaping the landscape. Automated finishing cells deliver repeatability at scale, reducing human variability. AI-driven process monitoring predicts defects before they occur, enabling proactive adjustments. Additive manufacturing introduces new challenges—and opportunities—in post-processing, where surface integrity dictates whether printed parts meet aerospace or medical standards.

Dimensional accuracy is necessary, but not sufficient. Surface integrity is where reliability, compliance, and performance converge. Treating surface finish as a strategic engineering function—not an afterthought—positions OEMs to lead in highly regulated sectors, like the aerospace, medical, and biotech markets.

Start with an audit of your finishing workflow. Identify variability, bottlenecks, and gaps in process control. Many failures originate in uncontrolled manual operations—eliminate them where possible.

Invest in metrology. Move beyond Ra to full surface characterization. Tools like interferometers and profilometers aren’t luxuries—they’re necessities for high-performance components.

Collaborate with suppliers. Ensure their finishing processes align with your functional requirements and compliance obligations. Surface integrity is a shared responsibility across the supply chain.

Leverage digital tools. Closed-loop feedback systems and statistical process control (SPC) for finishing operations enable continuous improvement and traceability. In an era of Industry 4.0, finishing should be as smart as machining.

Engineers who master surface integrity don’t just make better parts—they win markets. Lifecycle cost reduction is the first payoff. Components with optimized surfaces experience fewer failures, less rework, and longer service intervals. That translates into lower total cost of ownership for the customer and higher margins for the manufacturer.