Hardness is one of the most critical mechanical properties in metal selection and design. It refers to a material’s resistance to localized plastic deformation—typically measured through indentation, scratching, or abrasion.

While often confused with strength or toughness, hardness is a distinct property that plays a pivotal role in determining wear resistance, machinability, surface durability, and load-bearing capacity. This makes it a critical property in applications ranging from aerospace fasteners to automotive gears.

In this article, we’ll review hardness as a mechanical property, how it’s measured, its impact on CNC machining operations, and how to pick the right material for your machined component when material hardness is a factor at play.

What is Hardness?

Hardness is defined as a metal’s ability to resist permanent deformation under concentrated force.

Unlike tensile or compressive strength, which measure a material’s response to distributed loads, hardness focuses on how a material behaves under localized stress. This makes it especially relevant in applications involving contact surfaces, cutting tools, and wear-prone components.

Several factors affect a metal’s hardness, including composition, heat treatment, grain size, and work hardening.

Composition

A metal’s resistance to localized plastic deformation (i.e., its hardness) is fundamentally influenced by its chemical composition. This includes the alloying elements, which increase hardness by introducing atoms that either form hard secondary phases or disrupt the base metal’s lattice structure, as well as precision hardening, a process that enhances hardness by forming fine, dispersed particles within the metal matrix that obstruct dislocation movement and stabilize the microstructure.

Heat Treatment

Heat treatment increases or decreases a material’s hardness by altering its microstructure through controlled thermal cycles. In steels, for example, processes like quenching and tempering transform softer phases into martensite or tempered martensite, significantly boosting hardness and wear resistance.

Grain Size

Smaller grain sizes increase a metal’s hardness by introducing more grain boundaries, which impede dislocation movement and strengthen the material. This relationship, described by the Hall-Petch equation, means that refining grain structure—through processes like cold working or controlled heat treatment—can significantly enhance hardness. Conversely, larger grains reduce boundary density and make deformation easier, lowering hardness.

Work Hardening

Work hardening increases a metal’s hardness by introducing plastic deformation that multiplies dislocations within the crystal lattice. As these dislocations interact and entangle, they create internal resistance to further movement, making the material harder and stronger. This effect is especially pronounced in ductile metals like copper, aluminum, and low-carbon steel, where cold working processes such as rolling, drawing, or bending can significantly elevate surface hardness. However, excessive work hardening can reduce ductility and make the material more prone to cracking under further stress.

How to Measure Hardness

Understanding how hardness is measured will directly inform decisions about material selection, manufacturing processes, and part performance.

Hardness is measured using several different standardized tests, and knowing the differences between those testing methods ensures accurate interpretation of supplier data and prevents costly mismatches between design intent and material capability.

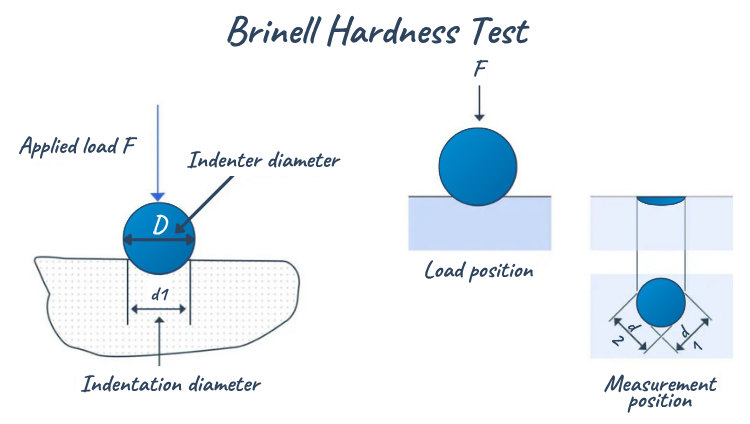

Brinell Hardness Test

The Brinell Hardness Test (BHN) measures a metal’s hardness by pressing a hardened steel or tungsten carbide ball into the material's surface under a specified load and then measuring the diameter of the resulting indentation.

BHN is calculated by dividing the applied load by the surface area of the indentation, providing a reliable indication of the material’s resistance to deformation.

Rockwell Hardness Test

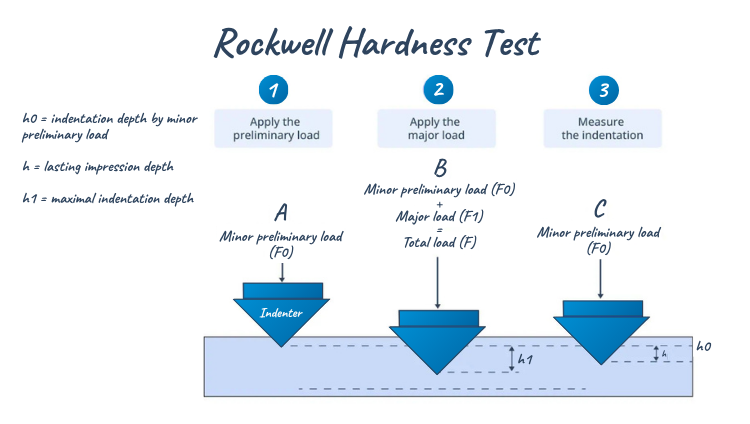

The Rockwell Hardness Test (HR) evaluates a metal’s hardness by measuring the depth of penetration of an indenter under a minor preload followed by a major load. Unlike the Brinell test, which measures the size of an indentation, Rockwell quantifies hardness based on how far the indenter sinks into the material, making it faster and more suitable for production environments.

The test uses different scales (e.g., A, B, C) depending on the material type and the indenter used—typically steel balls or diamond cones.

Vickers Hardness Test

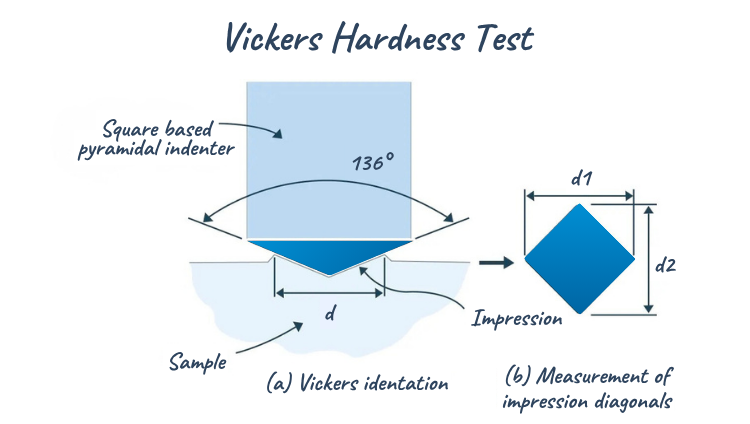

The Vickers Hardness Test (VHN) measures a metal’s hardness by pressing a diamond-shaped indenter into the material’s surface under a precise load. Unlike Rockwell or Brinell tests, Vickers relies on an optical measurement of the diagonal length of the resulting indentation to calculate the Vickers Hardness Number (VHN or HV), making it ideal for small parts, thin sections, and surface coatings.

Its wide applicability and high precision make it especially useful in microhardness testing and in evaluating case depths after surface treatments. The standardized test provides consistent results across a range of materials, including very hard alloys and soft metals. Because it uses a single type of indenter and a geometrically consistent method, it allows for easy comparison across different materials and hardness ranges.

|

Feature |

Brinell (BHN) |

Rockwell (HR) |

Vickers (VHN or HV) |

|

Indenter Type |

Hardened steel or tungsten carbide ball |

Steel ball or diamond cone (Brale) |

Diamond pyramid (square-based) |

|

Load Range |

Typically 500–3000 kgf |

Varies by scale (e.g., 60, 100, 150 kgf) |

1 gf to 100 kgf (micro to macro range) |

|

Measurement Basis |

Diameter of indentation |

Depth of indentation |

Diagonal length of indentation |

|

Best For |

Castings, forgings, coarse materials |

Production parts, metals, polymers |

Thin materials, coatings, microstructures |

|

Surface Requirements |

Flat, relatively large surface |

Minimal prep; small surface acceptable |

Highly polished surface required |

|

Precision |

Moderate |

High (especially in controlled environments) |

Very high; suitable for microhardness testing |

|

Standardization |

|||

|

Conversion to Other Scales |

Possible but approximate |

Widely used; conversion charts available |

Good correlation with tensile strength |

|

Common Applications |

Heavy industrial components |

General manufacturing, QC |

Aerospace, electronics, surface treatments |

Each test method serves a distinct purpose depending on the material type, geometry, and required precision. Brinell is ideal for bulk materials and rough surfaces, Rockwell excels in fast, repeatable production testing, and Vickers is unmatched in versatility—especially for small parts and layered materials.

When comparing hardness values across suppliers or RFQs, it's critical to note the test method used, as direct conversion between scales can introduce error if not properly contextualized.

So choose one that’s appropriate to the material type, geometry, and application of your machining project to get the most accurate, relevant results.

Hardness in Commonly Machined Metal

Hardness is a key attribute to assess when evaluating materials for CNC machining project. Materials with higher hardness offer superior resistance to deformation and surface wear, resulting in components that deliver greater longevity, simplified cleaning, and consistent performance in demanding environments.

While selecting a harder material typically enhances wear resistance, it often comes at the expense of toughness. For example, glass is highly hard but has very low toughness, making it susceptible to fracture under impact. Conversely, many plastics exhibit excellent toughness but are generally less resistant to surface wear and impact damage compared to metals.

The table below ranks the most commonly used metals in CNC machining from softest to hardest, with ranges accounting for the variety of alloys you see in a given metal (e.g., Aluminum 6061, Aluminum 6082, and Aluminum 7075).

|

Metal |

Hardness (Brinell Scale) |

|

Copper |

57 – 83 |

|

Brass |

61 – 141 |

|

Aluminum |

30 – 150 |

|

Bronze |

65 – 172 |

|

Monel |

110 – 225 |

|

Inconel |

116 – 240 |

|

Titanium |

180 |

|

Steels |

167 – 380 |

|

Stainless Steels |

360 – 440 |

In the instance where a traditionally hard metal won’t suit your project, there are options for making a low-hardness metal harder, if that particular material fits your project better. For example, solution annealed stainless steel 17-4 is less hard than the same alloy that’s been heat treated.

Mild steels, carbon steels, alloy steels, and aluminum alloys are commonly treated to make them harder. See the table below:

|

Treatment Process |

Purpose |

Compatible Metals |

|

Anodizing |

To enhance metal corrosion resistance, durability and appearance. |

Aluminum |

|

Carbonitriding |

To increase hardness and wear resistance whilst maintaining a tougher car. |

Steels and certain iron-based alloys |

|

Carburizing |

To increase the surface hardness of the metal part, while keeping the core soft. |

Mild steels |

|

Case Hardening |

||

|

Flame Hardening |

To increase hardness and wear resistance of specific areas of metal components. |

Carbon steels and steel alloys |

|

Induction Hardening |

||

|

Nitriding |

To improve hardness, wear resistance and fatigue strength of metal whilst maintaining a more ductile core. |

Steel and iron-based alloys |

|

Precipitation Hardening |

To increase the hardness & strength of the metal alloy. |

Aluminum and stainless steel |

|

Quenching |

To increase the hardness of the steel alloy. |

Mild steels, alloy steels, and tool steels |

How Hardness Impacts Machining

In CNC machining, hardness influences everything from tool wear and cycle time to surface finish and dimensional accuracy. This is important to keep in mind as you're selecting your part's material, defining tolerances, or choosing a machine shop if you aren't producing the part in-house.

Tool Wear

When machining harder materials, tool wear becomes the dominant concern. High hardness means greater resistance to deformation, which translates into higher cutting forces and elevated temperatures at the tool-workpiece interface. This accelerates wear mechanisms like abrasion, adhesion, and diffusion, especially in carbide and high-speed steel tools. To combat this, engineers often turn to coated tools, optimized geometries, and advanced toolpath strategies—but these come at a cost, both in tooling and cycle time.

Surface Finish

Surface finish is another area where hardness exerts influence. Harder materials tend to produce cleaner shearing during cutting, which can improve surface integrity if the tool is properly matched to the material. However, if the tool is underperforming or the setup isn’t rigid enough, chatter and microfractures can degrade the finish. In precision applications—like aerospace or medical components—this can mean the difference between a pass and a scrap.

Machinability

Machinability is the umbrella term that captures how easily a material can be cut, and hardness is one of its core components. Materials with moderate hardness often strike the best balance between strength and machinability, while extremely hard alloys (like hardened tool steels or titanium aluminides) require specialized tooling and slower feeds. This impacts not only the economics of machining but also the feasibility of certain geometries or tolerances.

It’s helpful to think of hardness as a machining constraint, a cost driver, and a performance variable all rolled into one. Engineers who understand how hardness interacts with cutting mechanics are better equipped to make informed decisions about tooling, feeds and speeds, and process planning.

How to Choose the Right Hard Material

When engineers prioritize hardness in material selection, they’re typically targeting wear resistance, surface durability, and long-term mechanical integrity—especially in applications involving contact stress, abrasion, or high-cycle fatigue. Metals with high hardness (e.g., tool steels, tungsten carbide, or hardened stainless alloy) offer exceptional performance in this case. However, this advantage comes with trade-offs.

High hardness typically correlates to reduced machinability, increased tool wear, and challenges in achieving fine surface finishes. These materials demand slower cutting speeds, specialized tooling, and often post-machining surface treatments, which can drive up lead times, cycle times, and cost.

For applications where machinability, surface finish, or cost efficiency are critical, consider alternatives that balance moderate hardness with better processability. Materials like annealed steels, aluminum alloys, or precipitation-hardened grades offer sufficient mechanical performance while being far easier to machine and finish. In many cases, surface treatments—such as nitriding, carburizing, or PVD coatings—can be applied to softer substrates to achieve localized hardness without compromising bulk machinability.

This hybrid strategy allows you to maintain performance in wear-critical zones while optimizing manufacturability across the part. The decision hinges on understanding the interplay between material behavior, tooling strategy, and the functional demands of the final product.

For engineers, understanding how hardness affects machining operations is essential for optimizing process efficiency, ensuring part quality, and controlling costs. It informs everything from RFQ evaluations to tool selection and CAM programming.

.png?width=624&height=427&name=Ductility%20(2).png)