Manufacturing insights for engineers who live in the ± 0.0002" world

Engineering

- Amanda White

- March 3, 2026

It’s easy to view material cost as the primary driver of part cost. After all, aluminum is cheaper per pound than...

- Amanda White

- February 17, 2026

High-speed machining (HSM) is not just “faster machining.” It’s a fundamentally different approach that relies on high...

- Amanda White

- February 9, 2026

Titanium and Inconel are two of the most widely used exotic metals in high-performance sectors like semiconductor,...

- Amanda White

- January 19, 2026

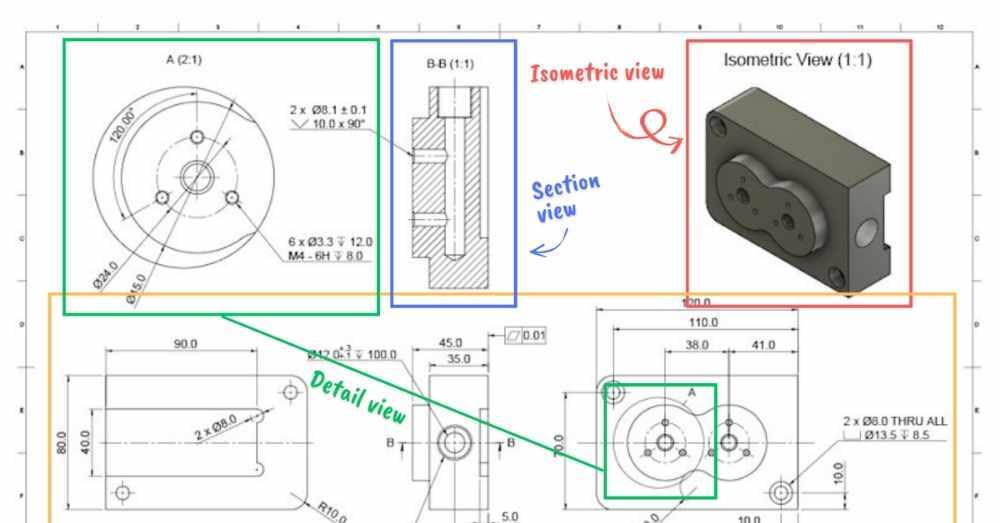

Technical drawings are the backbone of manufacturing communication. They translate design intent into actionable...

- Amanda White

- January 5, 2026

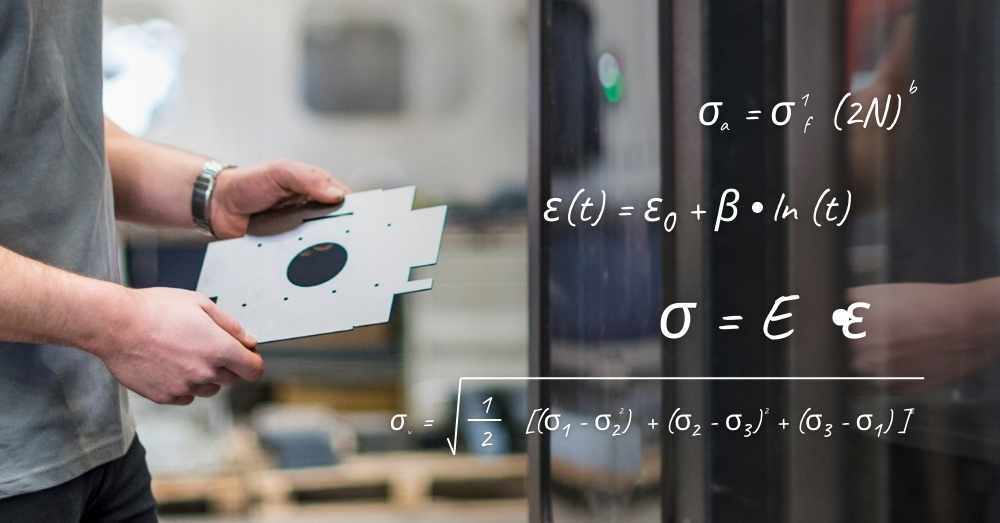

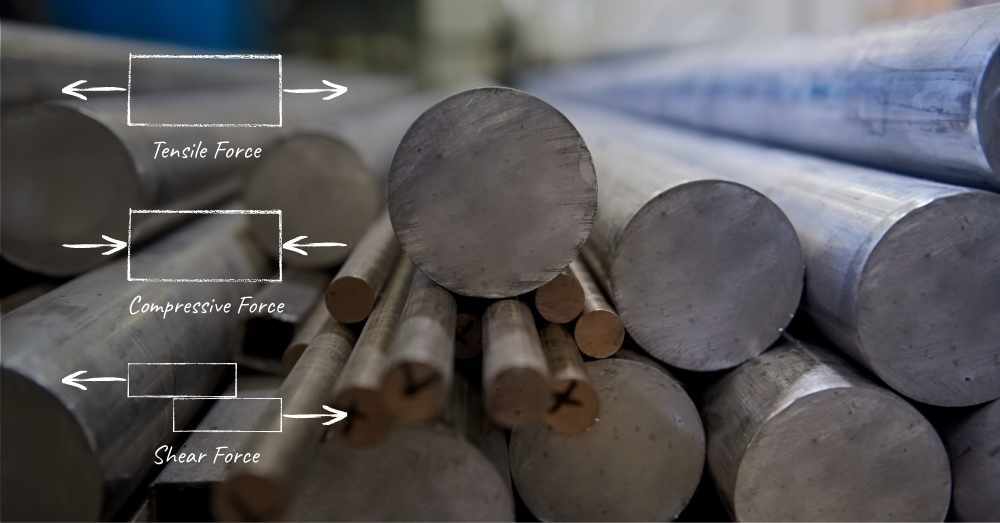

When designing or analyzing components, understanding a material’s mechanical properties is essential for predicting...

- Amanda White

- December 29, 2025

Your part meets dimensional spec—but will it survive in service? That’s the question every engineer should be asking....

- Amanda White

- December 15, 2025

In aerospace and medical device manufacturing, precision isn’t optional. A single micron can separate a conforming part...

- Amanda White

- December 1, 2025

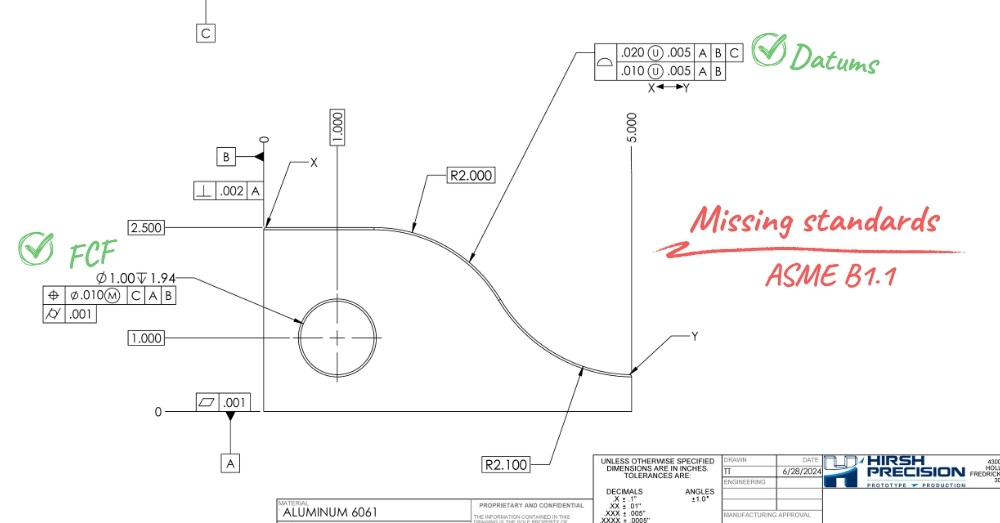

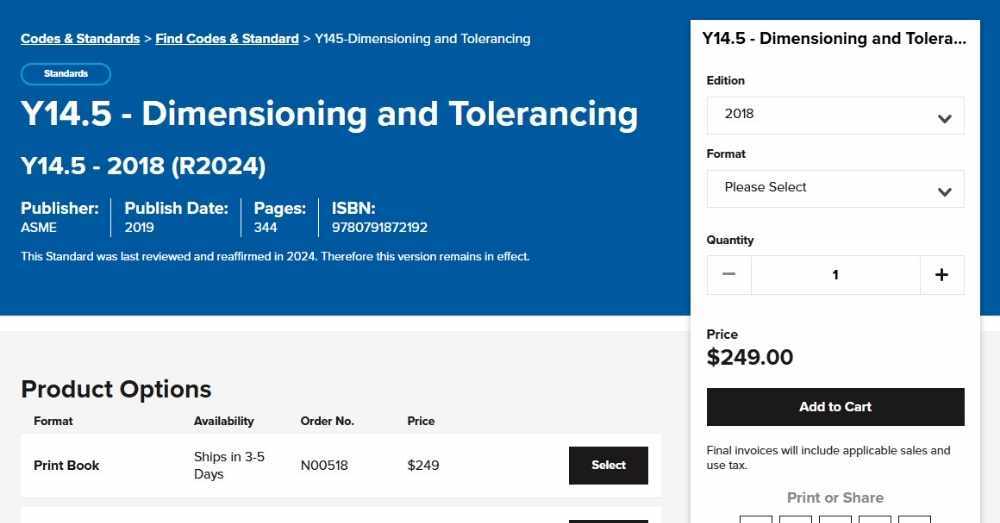

Geometric Dimensioning and Tolerancing (GD&T) is more than a set of symbols—it’s a language that defines how parts fit...

- Amanda White

- November 17, 2025

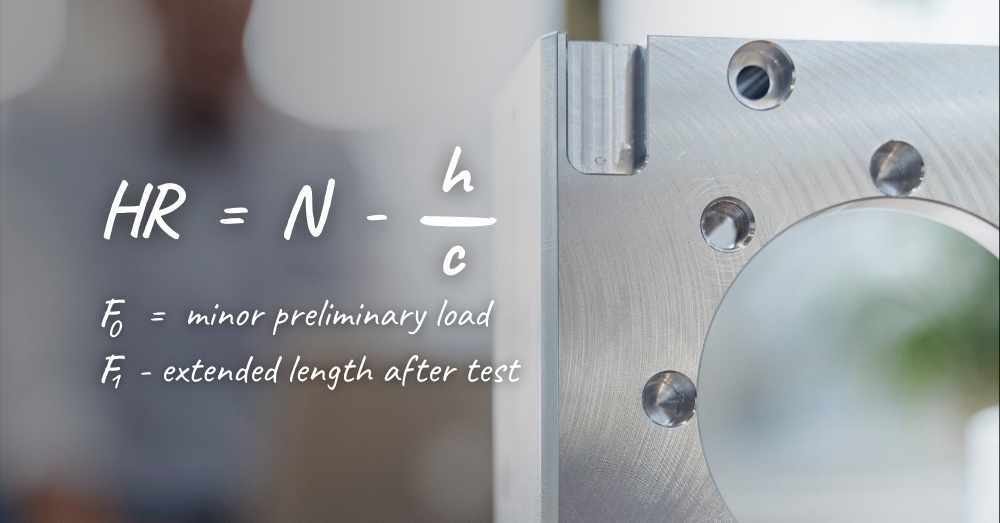

The hardness of a metal is influenced by its chemical composition, grain structure, and any heat treatments or alloying...

- Amanda White

- November 17, 2025

Threads are small features with big consequences. Whether you're designing a medical device housing or a structural...

- Amanda White

- October 27, 2025

That initial transition from low-volume to high-volume production can initially increase scrap rates, but it can also...

- Amanda White

- October 8, 2025

Minimizing a part’s weight increases structural efficiency and optimizes overall performance, while maintaining the...

- Amanda White

- September 22, 2025

Passivation is a chemical process that uses an acid solution to remove free iron and contaminants from a metal’s...

- Amanda White

- September 3, 2025

A component’s ductility directly influences its ability to perform in high-stress environments and withstand extended...

- Amanda White

- July 29, 2025

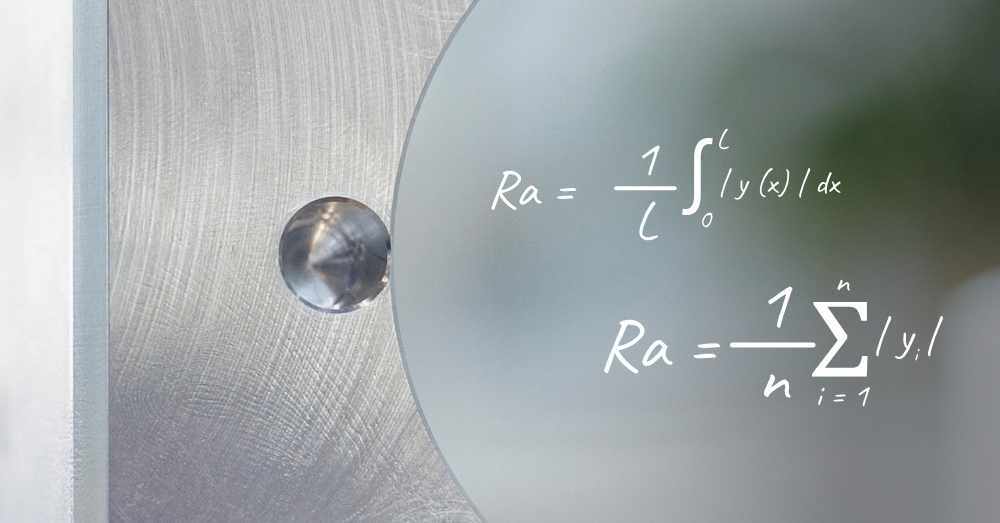

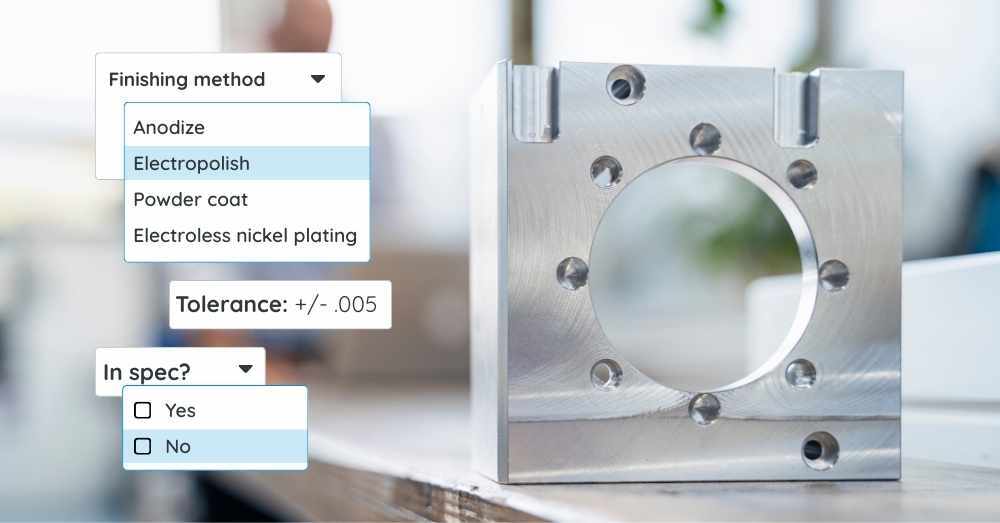

Surface finish is a critical part of the component manufacturing process. It can be for aesthetic purposes (e.g., if a...

- Amanda White

- July 10, 2025

Engineering drawings, also known as technical drawings, provide detailed 2D images of a part and include essential...

- Amanda White

- June 18, 2025

Strength is a key attribute to assess when evaluating materials for a CNC machining project. Stronger metals can...

- Amanda White

- June 12, 2025

GD&T is a symbolic language that’s used on engineering drawings to convey design intent to manufacturers. While it...

- Amanda White

- May 22, 2025

Surface finish plays a significant role in determining the final cost of your components, especially during high-volume...

- Amanda White

- April 22, 2025

How do you quantify material costs? That’s a pretty important question in the hardware development space, and by no...

- Tre Tiff

- March 26, 2025

For many OEMs, especially those who are in the prototype phase of a product launch, in-house machining is a great way...

- Chris Castaneda

- March 3, 2025

A coolant-through drill, also known as a through-coolant drill, is a type of drill bit that’s designed with internal...

- Chris Castaneda

- February 17, 2025

By the time you reach the machining phase, a significant amount of engineering and programming effort has already been...

- Tre Tiff

- February 3, 2025

Many OEMs rely on vertical integration to offset outsourcing issues or for prototype purposes. There are several...

- Amanda White

- August 20, 2024

Regarding machined components, material selection is one of the most impactful decisions your team will make while...

- Tre Tiff

- July 1, 2024

In this blog post, we'll delve into the crucial role of GD&T in product development and how these best practices can...